Maximizing Efficiency and Uptime: How Timely strapping machine repair Enhances Productivity

A Comprehensive Introduction of Strapping Machine Repair Techniques and Solutions

Strapping machines play a vital duty in packaging procedures, yet they usually encounter a series of usual issues. From mechanical wear to incorrect placement, these problems can lead to ineffectiveness and downtime. Understanding the signs of malfunction and employing efficient repair strategies is important. This introduction describes important approaches and tools needed for maintenance and troubleshooting. strapping machine repair. Figuring out when to tackle repairs individually or look for specialist help can considerably impact total efficiency.

Typical Issues Encountered by Strapping Machines

Strapping machines, crucial tools in product packaging operations, usually come across a series of usual problems that can disrupt operations. One regular trouble is incorrect tensioning, which can bring about over-tightened or loose straps, ultimately impacting plan stability. Additionally, damaged or worn seals might cause weak links, jeopardizing the general safety and security of the packaging. An additional typical concern involves misalignment of the strapping course, creating jams or disruptions in the strapping cycle. Dust and debris build-up can better aggravate these issues, bring about lowered machine efficiency. Operators might likewise face electrical malfunctions, such as faulty sensing units, which can impede the device's automated features. Ultimately, irregular strapping rates can result in hold-ups and inefficiencies in manufacturing. Dealing with these problems immediately is necessary for keeping peak performance and guaranteeing a smooth packaging process. Regular upkeep and troubleshooting are crucial to reduce downtime and prolong the longevity of strapping machines.

Identifying Signs And Symptoms of Malfunction

Determining symptoms of breakdown in strapping machines is crucial for reliable repairs. Typical mechanical problems usually materialize as unusual sounds or inconsistent strapping tension, while electric system failures might present as unpredictable operation or complete closures. Recognizing these signs and symptoms early can substantially minimize downtime and repair prices.

Usual Mechanical Issues

Mechanical integrity is crucial for the efficient procedure of strapping machines, yet different concerns can arise, resulting in malfunctions. Usual mechanical problems consist of damaged rollers, which might produce unequal stress or trigger the strap to slip. Imbalance of parts can lead to jams, hindering the production procedure. Furthermore, concerns with the tensioning system, such as a malfunctioning springtime, can cause irregular strap rigidity. Frayed belts or chains might additionally hinder activity, while damaged structures can endanger security. Operators ought to be vigilant for irregular operations or uncommon noises, as these may signify underlying mechanical failures. Motivate recognition and resolution of these concerns are vital to keeping perfect equipment performance and protecting against extensive downtime.

Electric System Failings

Breakdowns in the electric system of strapping machines can considerably impact their efficiency, equally as mechanical problems do. Determining signs and symptoms of electric failing is vital for prompt repair work. Typical indicators include intermittent power loss, which may show up as the device closing down unexpectedly or falling short to begin. Furthermore, unusual noises, such as humming or clicking, can indicate issues within the electrical components. A malfunctioning control panel may likewise present mistake codes or flickering lights, indicating underlying troubles. Furthermore, overheating elements or burnt integrates usually point to electrical overloads. Consistently checking these symptoms permits for very early discovery and intervention, inevitably decreasing downtime and boosting the maker's operational performance. Recognizing these signs aids specialists in diagnosing and attending to electric failings properly.

Step-by-Step Repair Techniques

When attending to the fixing of a strapping device, a methodical method is crucial to assure durable and effective options (strapping machine repair). Initially, the specialist needs to carry out a comprehensive examination to recognize the source of the breakdown. This involves monitoring for visible damages and making sure that all parts are functioning correctly. As soon as the problem is isolated, the next step requires dismantling the machine carefully, documenting each step to promote reassembly

After disassembly, cleaning up the inner components is crucial, as dirt and particles can worsen troubles. The service technician needs to then change any kind of worn or broken parts, making sure compatibility with the existing system. Complying with repair work, reassembly should be implemented thoroughly, paying attention to positioning and fastening. Ultimately, checking the maker under functional problems is crucial to validate that repairs have resolved the concern, followed by routine maintenance checks to avoid future malfunctions.

Tools and Tools for Effective Repairs

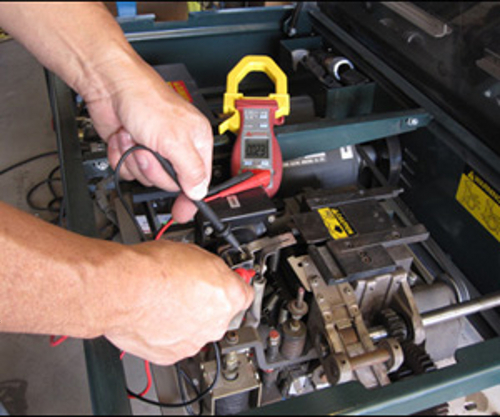

Effective fixings of strapping machines depend greatly on the right devices and equipment. Professionals need a range of hand devices, consisting of wrenches, screwdrivers, and pliers, to resolve mechanical issues effectively. Furthermore, specialized tools such as tensioning sealers and gadgets are important for assuring proper strapping performance.

Diagnostic tools, including oscilloscopes and multimeters, help in recognizing electric faults, while air pressure gauges work for pneumatic systems. Having access to replacement parts, such as belts and electric motors, enhances the repair work procedure, minimizing downtime.

A fully equipped workstation with sufficient lights and organization boosts efficiency throughout repairs. Safety gear, consisting of handwear covers and goggles, guarantees the technician's defense from possible dangers. By using the ideal devices and equipment, professionals can execute repair work properly, lengthening the life-span of strapping machines and preserving functional efficiency.

Preventative Maintenance Strategies

To assure the longevity and efficient procedure of strapping machines, carrying out preventative upkeep approaches is necessary. Regular evaluations play a crucial duty, allowing operators to determine deterioration prior to it rises right into significant problems. Secret parts such as electric motors, rollers, and belts should be taken a look at regularly for indications of damages or misalignment.

Lubrication of relocating components is an additional fundamental element, decreasing friction and preventing premature wear. Operators must follow the manufacturer's standards for lubrication periods and kinds of websites lubricants.

In addition, maintaining exact records of upkeep activities aids track the device's condition in time, guaranteeing that no significant aspect is forgotten. By prioritizing these preventative measures, companies can boost the reliability of their strapping machines, eventually decreasing downtime and repair work prices.

Repairing Tips for Quick Fixes

Although strapping machines are developed for toughness, they can come across periodic problems that interfere with operations. Identifying and resolving these problems quickly can lessen downtime. One usual problem is imbalance, which can usually be fixed by inspecting the positioning of the strapping material and readjusting the overviews accordingly. If the device stops working to band correctly, operators should inspect the tension settings and assure that the film is filled appropriately.

Another frequent issue is the presence of debris in the feed location. Consistently clearing any kind of blockages can improve performance. In addition, if electrical elements seem less competent, confirming power links and resetting circuit breakers can bring back operation. Operators needs to likewise analyze the securing mechanisms for damage, as worn components can result in poor seals. By using these fixing tips, operators great post to read can efficiently manage small issues and maintain the efficiency of strapping operations.

When to Look For Professional Assistance

Recognizing the signs of equipment malfunction is vital for maintaining functional performance. strapping machine repair. Seeking expert aid becomes required when repair work become complex or safety problems arise. Prompt intervention by experts can stop additional damage and ensure a risk-free workplace

Indicators of Machine Malfunction

How can operators recognize when a strapping maker remains in distress? Numerous indicators signal possible breakdown. Uncommon noises, such as squealing or grinding, frequently suggest mechanical problems. Irregular strapping quality, defined by loosened or poorly secured bands, might indicate problems with tensioning or securing mechanisms. Regular error messages on the control panel can be a clear indicator that the maker is not functioning properly. Operators ought to additionally keep track of for too much vibrations or getting too hot, which could direct to underlying mechanical failings. In addition, if the maker frequently jams or requires more frequent adjustments, it might be time to look for expert help. Recognizing these signs early can prevent additional damage and ensure the equipment operates effectively.

Facility Repairs Required

When operators observe consistent indications of breakdown in a strapping machine, such as uncommon sounds or frequent jams, it might show the need for complex repair services past regular maintenance. In such cases, it is necessary to analyze whether the issues come from inner components like sensors, gears, or electric motors, which require specialized expertise to deal with and detect. Additionally, problems involving the machine's electric systems or software program may necessitate expert intervention. Attempting to address these complexities without appropriate proficiency can result in additional damage, intensifying repair work prices and downtime. Consequently, when encountered with elaborate problems, drivers need to seek the help of experienced specialists who possess the technical abilities and experience essential to recover the strapping machine to the most effective working condition effectively.

Security Issues Involved

Safety and security ought to always be a key worry for drivers handling strapping machines, especially when intricate repairs are needed. In circumstances involving electric parts, high-pressure systems, or intricate mechanical parts, the danger of injury boosts significantly. Operators ought to identify the indications indicating that specialist help is necessary, such as unfamiliarity with the equipment's systems, relentless malfunctions, or the visibility of harmful products. It is important to abide by safety and security methods, consisting of putting on proper personal safety equipment (PPE) and ensuring the machine is powered down prior to trying any type of repairs. Seeking professional assistance not only mitigates dangers yet also guarantees that repairs are conducted appropriately, consequently expanding the machine's life expectancy and keeping operational effectiveness. Focusing on safety eventually secures both employees and tools.

Often Asked Questions

Just how Often Should I Solution My Strapping Machine?

Strapping machines must be serviced every six months to ensure peak performance. Regular upkeep helps avoid malfunctions, prolongs the machine's lifespan, and assurances constant strapping top quality, inevitably reducing operational downtime and fixing prices.

What Are the Finest Brands for Strapping Machine Parts?

Some of the very best brand names for strapping maker parts include Signode, Mosca, and Fromm. These manufacturers are recognized for their premium elements, toughness, and reliable performance, making them prominent options amongst market professionals.

Can I Repair a Strapping Machine Myself?

Yes, an individual can repair a strapping machine themselves if they possess the necessary skills and expertise. Nonetheless, consulting the guidebook and comprehending the maker's elements is important to assure reliable and secure repair services.

Exactly how Do I Discover a Competent Technician for Repairs?

To locate a certified professional for repairs, one ought to look for referrals from sector peers, consult on the internet evaluations, and validate certifications, making sure the professional has relevant experience with strapping machines for superior service high quality.

What Guarantee Options Are Offered for Strapping Machines?

Numerous service warranty alternatives for strapping machines typically include common supplier guarantees, expanded guarantees, and solution plans. These options differ in period and protection, ensuring defense versus issues and breakdowns for different periods post-purchase.

Recognizing signs and symptoms of malfunction in strapping machines is essential for effective repairs. When dealing with the repair of a strapping machine, an organized strategy is crucial to ensure effective and lasting remedies. Reliable repairs of strapping view machines depend greatly on the right devices and tools. When operators observe persistent signs of malfunction in a strapping device, such as unusual sounds or regular jams, it might indicate the need for complicated fixings past regular upkeep. Security should always be a main issue for operators dealing with strapping machines, particularly when intricate repair work are required.